Machines

EXTRUSION

> MACHINES > XLPE-IXPE FOAM PRODUCTION EQUIPMENT > EXTRUSION

> MACHINES > XLPE-IXPE FOAM PRODUCTION EQUIPMENT > EXTRUSION

PE TECH is a manufacturer of Chemical Cross-linked polyethylene foam sheet production line. (aka XLPE or PE-Xa) XLPE, Chemically crosslinked polyethylene foam, is crosslinked by DCP(Peroxide) raw material. It is produced in continuous rolls Resulting in a foam product with uniform, closed cells and smooth surfaces on both sides. XLPE foam is also available in sheets.

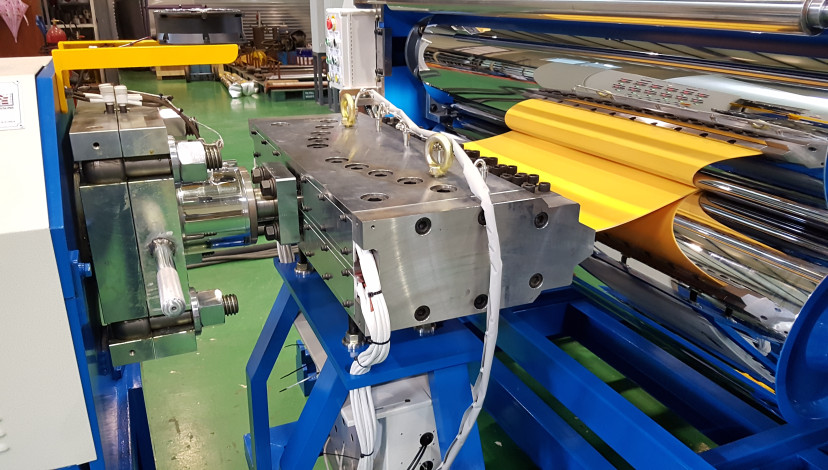

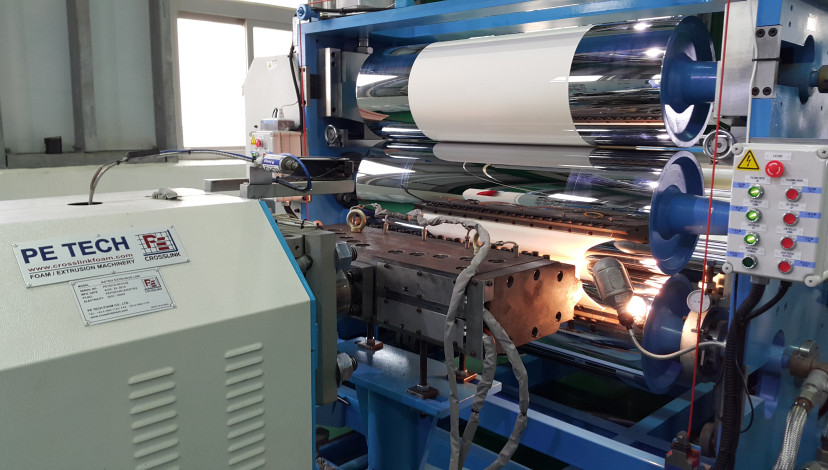

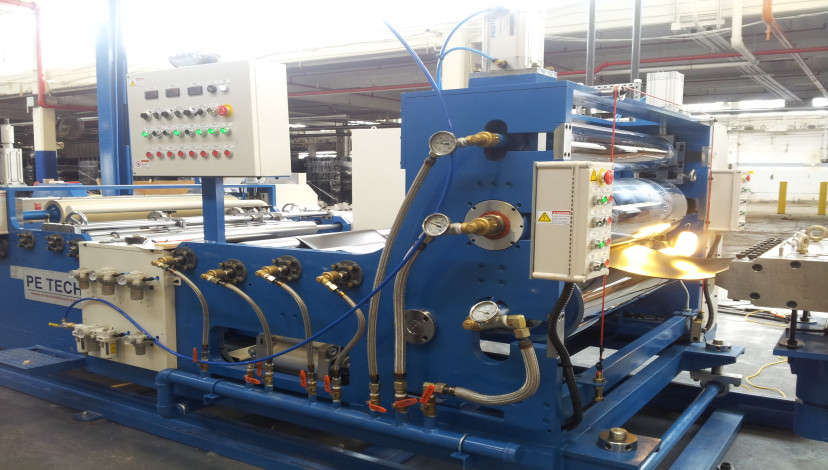

MATRIX EXTRUDER

Feature

| Model | Hopper capacity | Screw dia | LD ratio | Motor |

|---|---|---|---|---|

| PTH-EXT150 | 200 Liter | 150mm Single | 26:1 | 200~216hp |

COMPONENTS OF PTH-EXT150

- Gear box unit

- Cylinder (barrel) unit

- Screw unit

- Cooling unit

- Hopper loader unit

- Main driving motor unit

- A.C motor control enclosure

- Heater control enclosure

- Extrusion T-dies unit

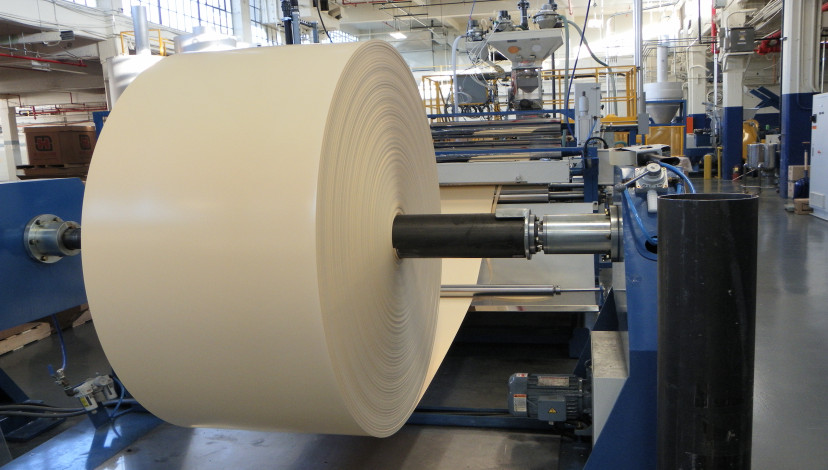

Matrix extruder makes rigid SOLID sheet using basic raw materials from

mixing line which Masterbacth pellet and LDPE resin.

That rigid SOLID XPE/IXPE sheet is semi-foamed product for foaming process.

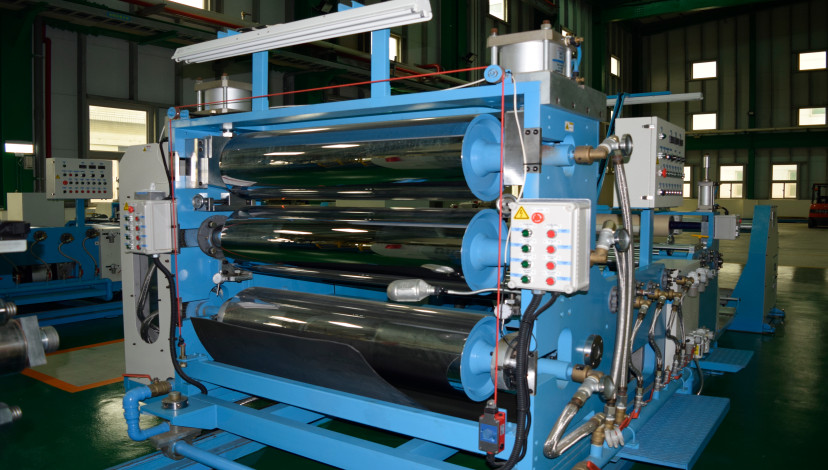

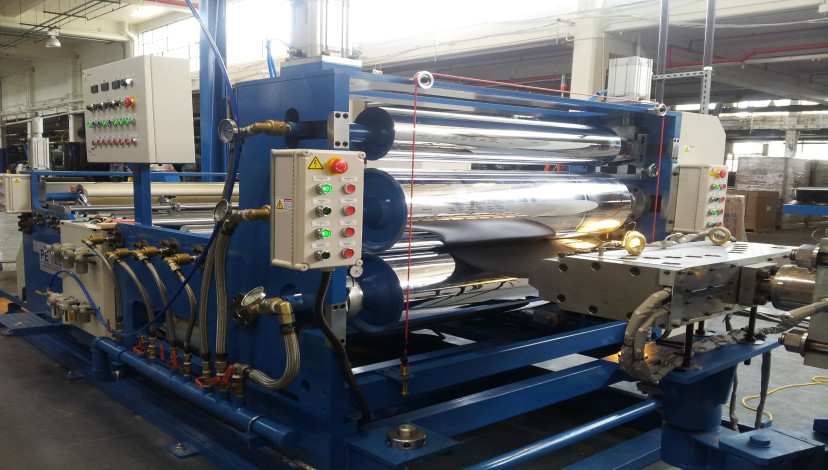

3 step polishing roller unit has supported to make a shine surface and thickness control.

3 STEP POLISHING ROLLER UNIT

Feature

| Model | Roller Type | Cylincer Type | Reducer | Motor |

|---|---|---|---|---|

| PTH-PLR3 | Forming 350Φ Touch 213Φ Cooling 114Φ Guide 114Φ |

Air or Hydraulic | 10:1 | 5hp |

COMPONENTS OF PTH-PLR3

- Polished rollers

- Driving motor

- Water pipe unit

- Air cylinder parts unit

- Hydraulic parts unit (instead of Air type)

- Anti static blower

- Matrix re-winder unit

- Hoist and crane unit

Matrix extruder makes rigid soild sheet using basic raw materials from

mixing line which Masterbacth pellet and LDPE resin.

That rigid soild XPE/IXPE sheet is semi-foamed product for foaming process.

3 step polishing roller unit has supported to make a shine surface and thickness control.